Wall facing

1) Faceted PlayBlok facing blocks

A procedure for easy and strong fastening of facing blocks so that they stick forever. The below link refers to an exact instruction for use of flexible glue, anchors and base bars:

Work procedure for cementing facing tiles (PDF, 12 MB)

- PlayBlok facing blocks

- FLEXKLEBER elastic cement

- Solid anchor or Polystyrene anchor with larger hole for fastening: CZK 41.50 each, excl. VAT

- Solid base bar or Base bar with larger hole for fastening: CZK 294 each, excl. VAT.

(Both anchors and bars are made of stainless steel. The bar length is 1,990 mm.)

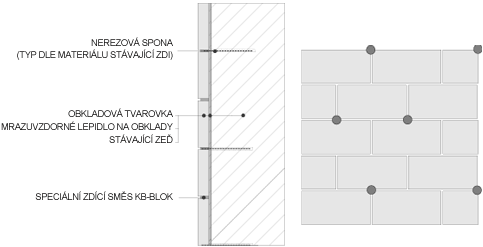

The facing blocks have to be built to the KB-BLOK system walling principles. Most importantly, lay them with 8-10 mm joints to adhere to the basic product modular grid.

Before facing, any substrate unevenness has to be evened using cement mortar.

For application with facing cement (frost-resistant for exterior use), only use cement mortar for the joints. Special jointing compounds for ceramic tiling have not yet been tested.

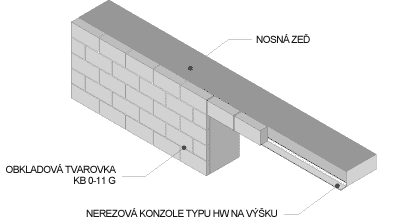

The facing has to be anchored to the wall with stainless steel ties while walling. If applying facing to an existing wall, use ties for additional positioning (fasteners). Use a suitable type of stainless tie depending on the wall material anchored into. When walling the load-bearing wall and the facing simultaneously, ties are inserted in the laying joints continuously.

Special stainless steel anchors are used for door lintels.

Surface priming with hydrophobic coat

Ground building block facing has to be treated with a surface primer. The hydrophobic product used should meet several basic requirements:

- it has to be designed for concrete materials;

- it has to be resistant to UV radiation;

- it has to permit “wall breathing”;

- it has to be inert to concrete.

There are many products on the market that meet these criteria. The following have been tested successfully with the KB-BLOK system:

- KERASEAL by Mapei – for interiors only,

- CHRYSO HD by Chryso – for both interiors and exteriors,

- LADAX BAF 3 by Ladax – for interiors.