Walling methods

Execution method

Compared to other types of building blocks, walling with KB-BLOK systém building blocks has a number of advantages. However, the following process requirements have to be observed:

- Proper use of the KB-BLOK systém assumes construction execution based on project documentation, which respects the system dimensional module (see Chapter 1.1).

- The exact shapes of the KB-BLOK systém elements requires a highly professional approach to the laying jobs, not only when walling but also when preparing the foundation (precise levelling).

The construction procedure itself is identical to walling with ordinary elements, with a 10 mm wide joint, and building can proceed without heavy-duty equipment.

Joint finish

Structures made of KB-BLOK systém building blocks are built using cement mortar. Use the KB-BLOK Special Walling Compound or MC 021 cement mortar.

Both horizontal and vertical joints have a prescribed width of 10 mm The accuracy of joints has to be maintained for reasons described in the chapter related to system modular coordination. The accuracy can be achieved using a batten on which you mark the necessary spacings (for vertical walling): 190/10/190/10/190...; for horizontal: 390/10/390/10/390...).

Horizontal joint:

The joint has to be made so that the final thickness is 10 mm. This can be achieved in several ways:

a. Applying mortar using a “mortar sledge”

b. Applying mortar using a bricklayer’s wire

c. Applying mortar without any jigs – for experienced bricklayers

Vertical joint:

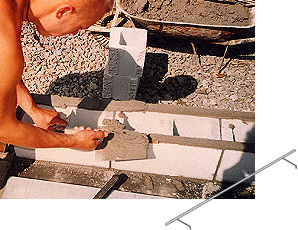

The vertical joint width is similarly achieved. Apply mortar to the building block in a tilted position with a trowel (prepare several tilted building blocks on a plank).

The vertical joint width is similarly achieved. Apply mortar to the building block in a tilted position with a trowel (prepare several tilted building blocks on a plank).

If you only filled the joints after laying the building blocks, you would fill the hollows. To level the blocks, exclusively use wooden or rubber mallets.